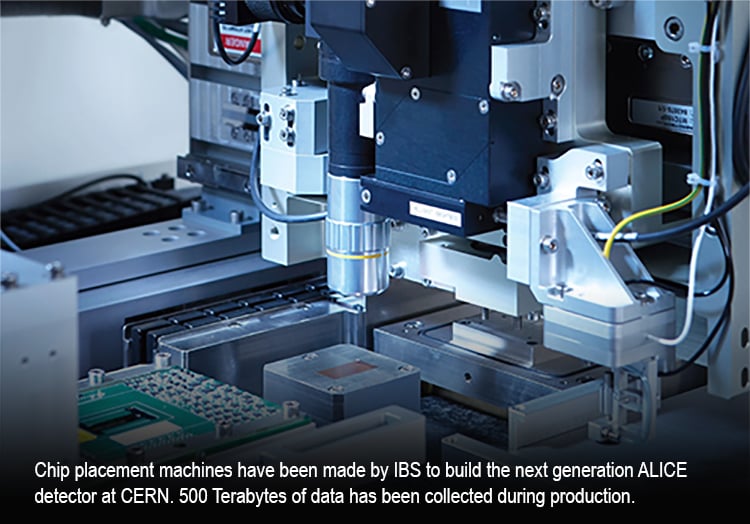

For over 25 years, IBS Precision Engineering has been providing precision engineering solutions for the high-tech manufacturing sector, scientific instrument makers and research institutes. As a part of the international precision engineering community, we deliver world-class measurement machines and measurement systems for ultra-precise parts, processes or instruments. We also design and manufacture modules which are integrated into our customers products, machines or instruments to ensure they achieve extreme geometric or kinematic accuracy.

We have the opportunity to work on some of the most challenging projects, from precision placement machines for CERN to optics measurement for next generation semiconductor production. Across the board we see exciting trends in precision demands. Here we share just some of those trends in the industries we serve.

Semiconductor Equipment

When it comes to semiconductor fabrication equipment, such as lithography machines, the hunger for precision does not stop. Greater precision is needed for smaller structures. For example, in integrated circuit production typical layer to layer accuracy (overlay) during fabrication is now at 1.5 nanometres (approximately 1/50,000 of the width of a hair). And the mirrors integrated in the latest generation of lithography machines require a form accuracy one hundred times smaller again.

As the targeted precision increases, so too does the skill required to control potential disturbances within the machine. Unwanted temperature gradients, for example, or unintended vibrations at extremely low levels, can have significant impacts on performance and must be managed. As each functional part of a machine becomes more complex, the measurement strategy needed to achieve precision also becomes more challenging. This strategy must take into consideration each of the parts and their interrelationships.

With digital twins, complex systems are described in models. Simulations are used to identify influences of thermal behaviour, flow induced behaviour or dynamics. Kinematic and dynamic system modelling is applied to analyse and improve motion performance. In advanced machines, models are transferred to real-time software embedded in the system.

With digital twins, complex systems are described in models. Simulations are used to identify influences of thermal behaviour, flow induced behaviour or dynamics. Kinematic and dynamic system modelling is applied to analyse and improve motion performance. In advanced machines, models are transferred to real-time software embedded in the system.

With the stakes so high in semiconductor production, quality has to be embedded from concept onwards. Testing tools become more in demand to qualify part performance at every stage of manufacturing.

At IBS we now design to the picometer. Making virtual machines has become the norm. And big data strategies have become a standard requirement as machines become more intelligent.

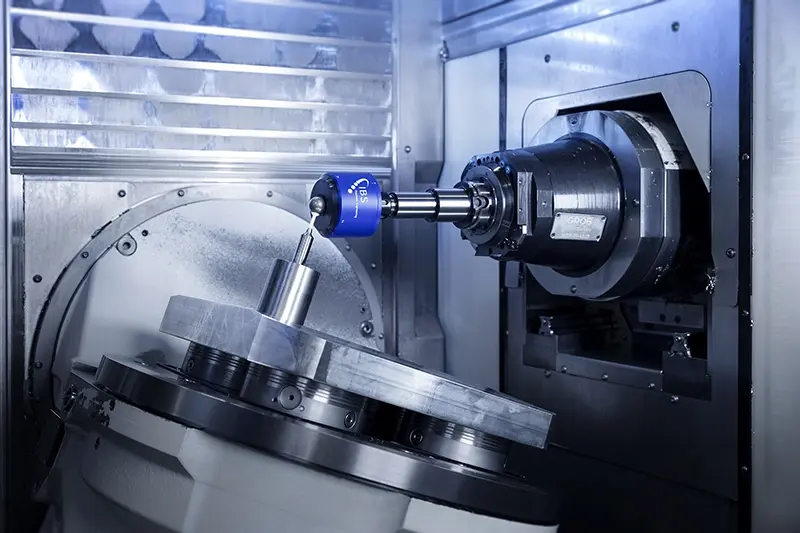

Machine Tool

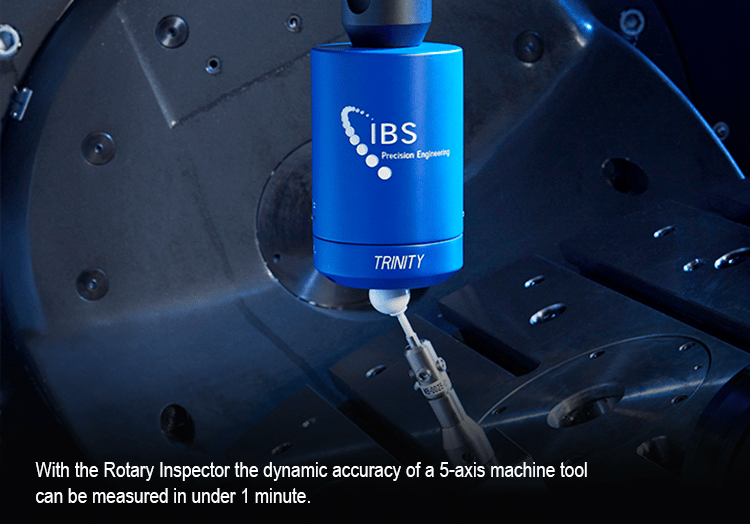

Complex workpieces such as turbine blades, impellors and medical protheses, are typically manufactured on 5-axis machine tools. For machine tool builders and users, it is imperative to reduce geometrical, surface or form errors to a minimum. Machine qualification prevents errors before they occur. Qualification tools must be fast enough to integrate into the production schedule and intelligent enough to measure the full dynamic behaviour of the machine. The latest generation of measurement systems in the field can measure the full accuracy of a machine tool in under a minute. Such tools enable predictive maintenance, which extends the uptime and lifetime of the machine.

Production processes are increasingly required to be certified for production repeatability, quality and safety reasons. Application of international standards (such as ISO 10791-6), enables machine builders, machine users and end customers to agree on common quality goals.

Production processes are increasingly required to be certified for production repeatability, quality and safety reasons. Application of international standards (such as ISO 10791-6), enables machine builders, machine users and end customers to agree on common quality goals.

Industry 4.0 helps businesses to improve cost efficiency, become customer centric and drive agility. Central data management and analysis, real-time performance insights and improvements by software compensation are all bringing this next revolution to reality.

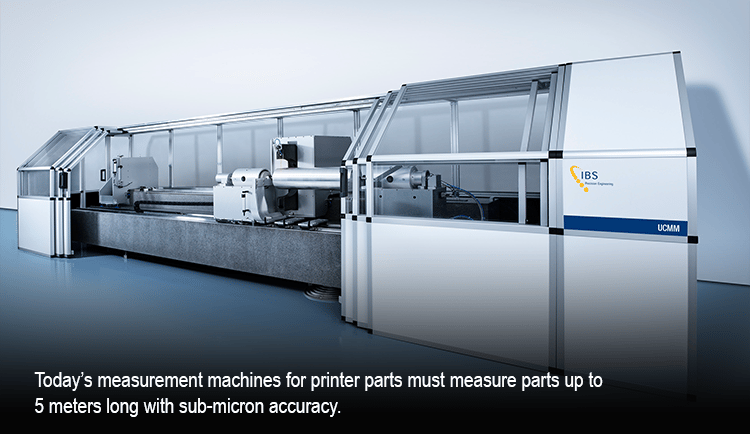

Printing Equipment

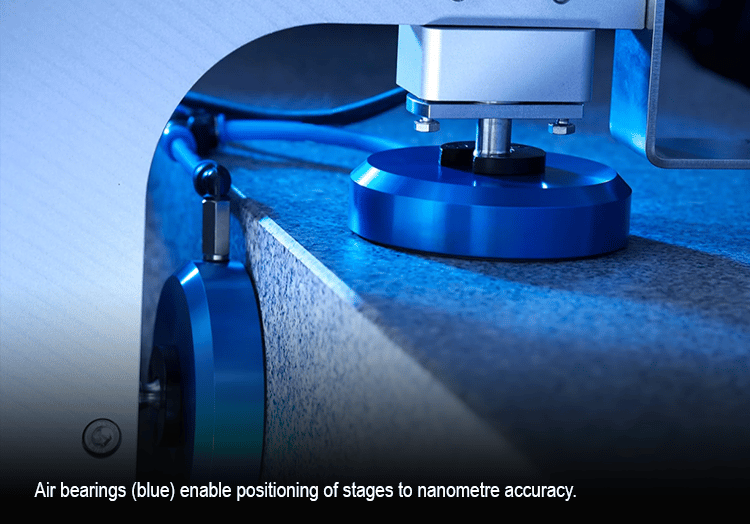

Printing has required precision for many decades as the human eye is very sensitive to accurate registration of colours. Today however this has to be achieved over metres of surface. Thus, large cylindrical printing equipment parts must achieve sub-micron (<10-6 m) level accuracy where dimensions have grown to approximately 5 metres.  With advanced printing technologies, not only visuals are printed but devices such as electronics. This requires control of the substrate during the printing process with sub-micron accuracy, whether the substrate is thin (glass) or flexible (plastic foils). This precision can be achieved with technologies such as air bearings for transporting or stabilising these substrates. In-line inspection interferometers can be applied to verify these accuracies.

With advanced printing technologies, not only visuals are printed but devices such as electronics. This requires control of the substrate during the printing process with sub-micron accuracy, whether the substrate is thin (glass) or flexible (plastic foils). This precision can be achieved with technologies such as air bearings for transporting or stabilising these substrates. In-line inspection interferometers can be applied to verify these accuracies.

Moving from 2D to 3D printing, these accuracy requirements becomes spatial. Here precision motion components are key to achieve the required volumetric repeatability. The latest 3D (polymer) printers have the capability for sub-micron feature printing. For production this requires extremely accurate x,y and z stages. Air bearings allow to move without friction at high speed, essential to achieve both accuracy and productivity.

Embracing the challenge

Embracing the challenge

In the field of precision engineering, the challenges never stop. Luckily nor does the ingenuity of the engineers who love to meet these challenges!

Follow us on LinkedIn for more news