- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

The positioning accuracy of any machine tool is of vital importance. It governs how and when your end product is within tolerance and defines your productivity. Over time accuracy can fall off and with it effective output. The Position Inspector measuring system delivers rapid and precise measurement for the positioning accuracy of your machine's linear axes.

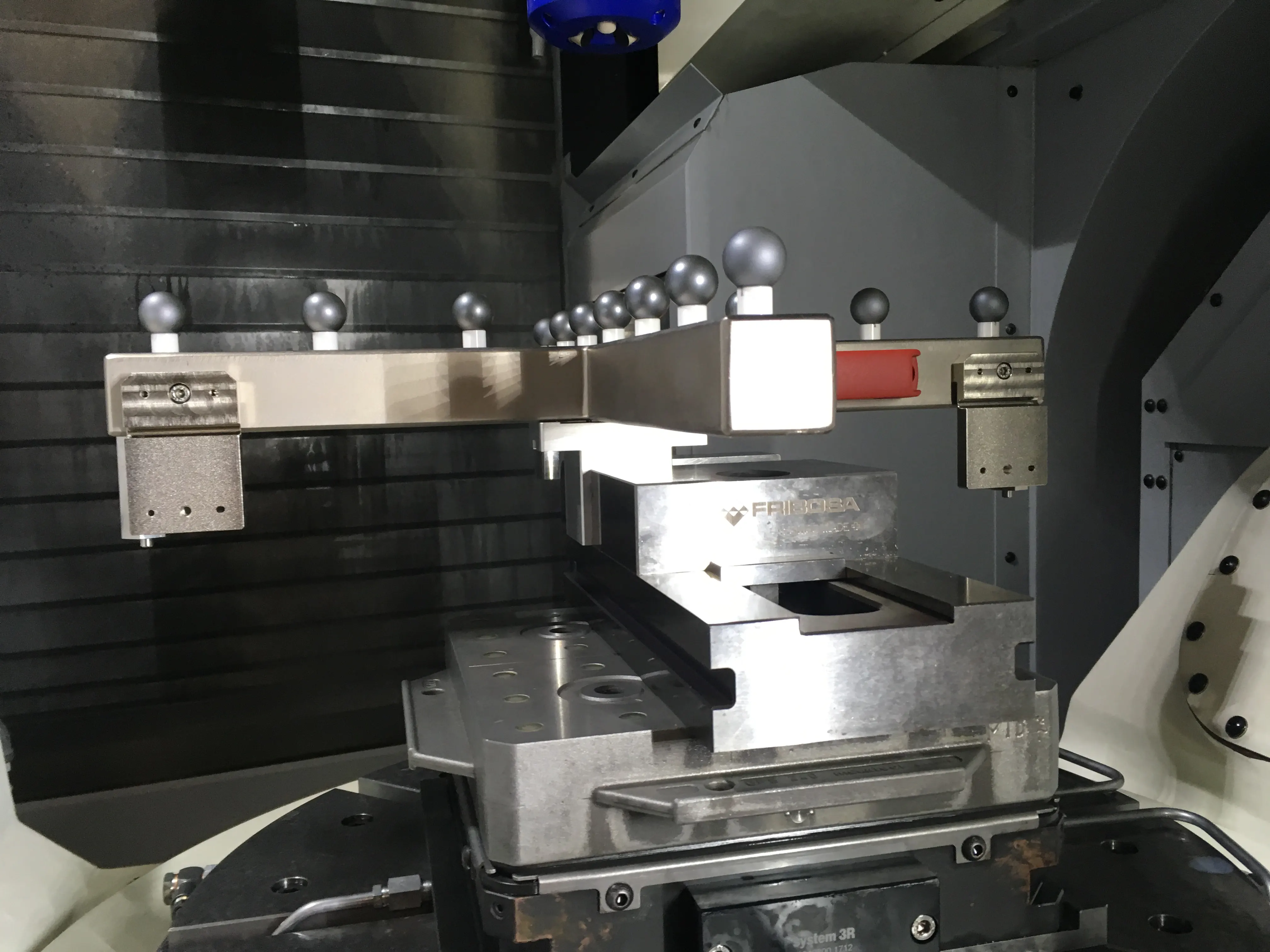

The Position Inspector consists of a cross shaped artefact that is placed on the machine table and a wireless measurement probe that is inserted in the spindle. The artefact consists of 13 precision balls whose position is known with sub-micron accuracy. The cross is aligned with two of the machine’s linear axes and the machine is commanded to move the probe to each of the balls in a set sequence. The probe measures the error that occurs in positioning of the probe in X, Y and Z directions, and hence calculates the linear axes errors. The artefact can be pallet mounted and the probe placed in the toolchain.

Provided in the Position Inspector kit

The Position Inspector kit includes a wireless Trinity probe plus battery charger. A traceable cross-shaped artefact is supplied with calibration certificate. The Position Inspector Software App is included. A standard NC program library is available for all major machine configurations and controllers for rapid integration. Requested programs from this library are supplied with the kit.

Laser interferometers are commonly used to calibrate the linear axes of machine tools. Despite that these instruments are well known and used, the required measuring time is problematic for application in industry. What is more, such measurements cannot typically be automated, require an expert, and protection covers have often to be removed to gain access.

The Position Inspector is designed to overcome these issues and provide a rapid, automatic method for calibration of machine linear axes. It puts an instant “health check” at hand during normal production, delivering fully automated measurement in less than five minutes to derive the total machine positioning accuracy.

Measurements are made according to international standards (ISO 230). Results are presented in a digital quality report as well as an interactive history function.

Unique strengths of the Position Inspector: