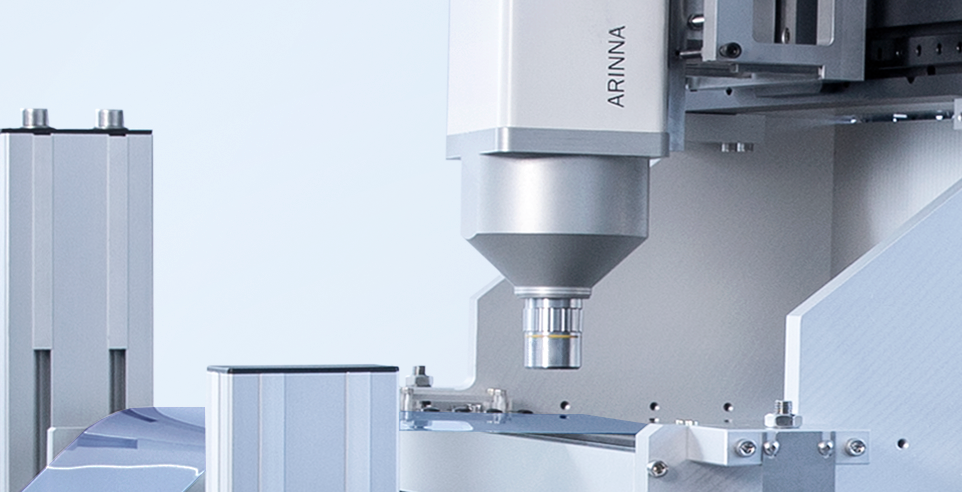

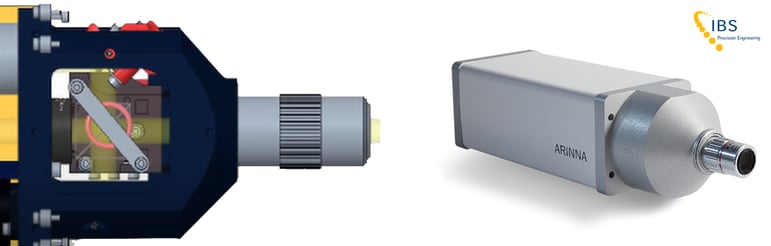

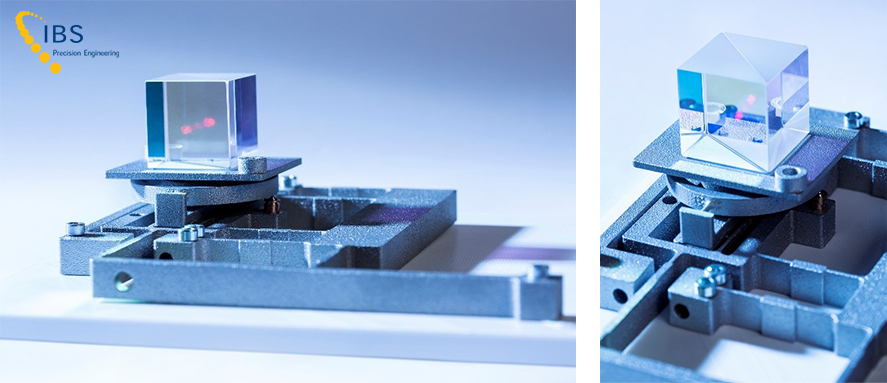

At IBS precision Engineering we deliver solutions that enable our customers to manufacture their products or instruments with the utmost accuracy. As a new entry to our portfolio, our optical measuring system ARINNA offers high-speed interferometry for areal surface measurements of micro and nanoscale structures. Designed for in-line use, it needs to be compact, rugged and fast whilst delivering nanometer accuracy. This system consists of a series of optical components that guide light through the system. Mechanical engineering students from Fontys Hogeschool in Eindhoven were asked to redesign the optical mounts that are part of the measuring system to shorten the production time. The question we had for them: can you design monolithic 3D-printable adjustable optical mounts to replace our existing mounts?

Optical measuring system ARINNA

Optical measuring system ARINNA

Rens van der Nolle, Senior Mechanical Engineer at IBS: “3D printing offers the potential for new monolithic designs, which could provide better adjustment ability compared to traditionally built mounts. In this project we aimed to establish general design rules for designing monolithic mounts for such precision mechanics.

Mechanical Engineering students Fontys Hogeschool:

Mechanical Engineering students Fontys Hogeschool:

Jeroen Raijmann, Renate Langendoen, Chris van Lieshout and Leonardo Strik.

After they were introduced to IBS Precision Engineering and the project, the group of students faced with this challenge set to work. Student Renate Langendoen explains some of the steps they took: “Together with IBS, we started with drawing up a program of requirements for the project. We organized brainstorm sessions to think of possible solutions and choose the right methodology for the project. By desk research we found the theoretical research data to help us with our project. And that led us to start designing according to the agreed parameters. In Matlab we checked the FEM analyses by hand calculations. The final step was to print the prototype and test it using a laser and a target.”

Jeroen Raijmann adds: “We had quite some challenges to solve during this project. First of all, framing the project in general. We selected one of the 4 optical parts that IBS wanted to redesign. We opted for the most complex mount: the beam splitter. The shape of this mount was challenging because all DOFs had to be editable except the z-translation, movement could only be created from above or below the beam splitter, maximum rotations of plus/minus 5 degrees had to be achieved, and it had to fit in the current framework of the ARINNA.”

The most challenging mount: the beam splitter

The most challenging mount: the beam splitter

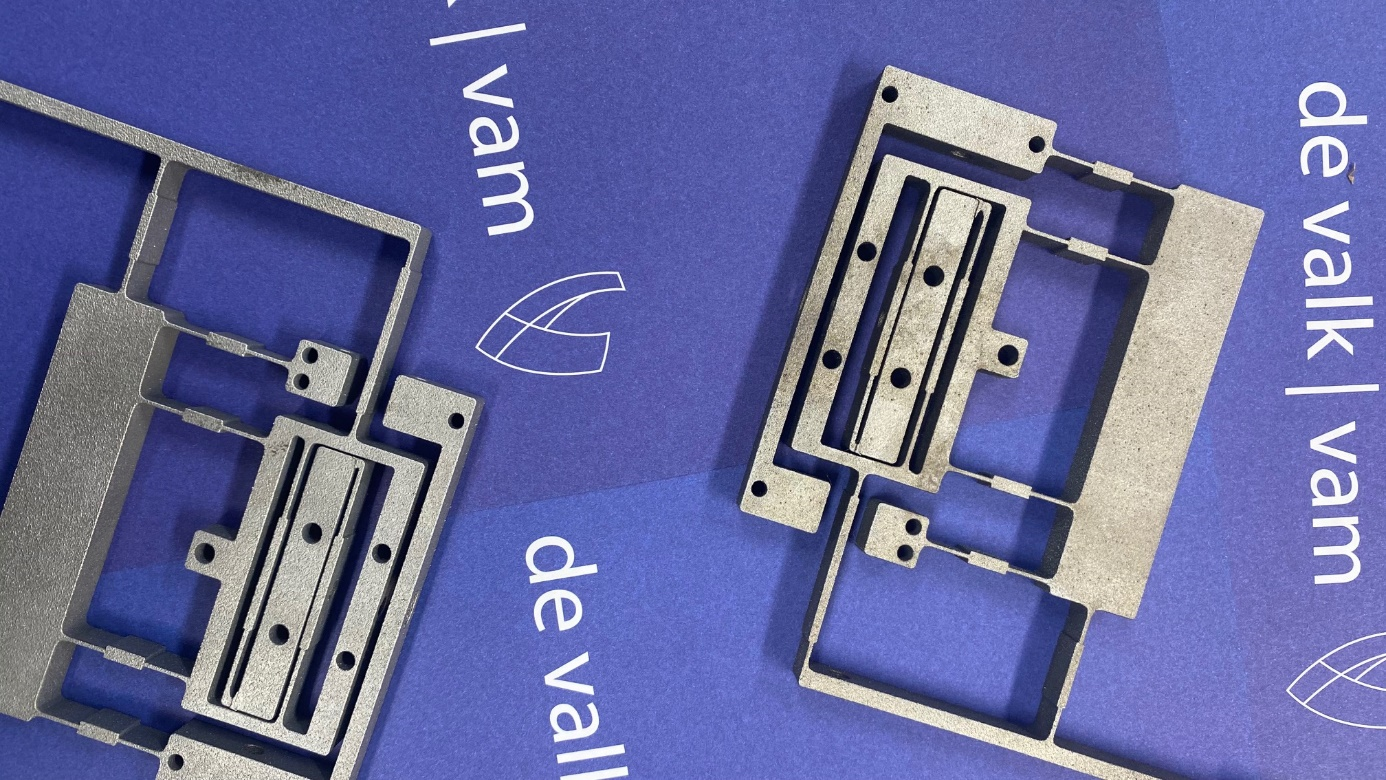

“Another challenge was the choice of the right material for 3D printing”, says student Leonardo Strik. “Steel initially seemed like an obvious choice, but our models showed that aluminium has a better range of motion. In addition, we also had to consider the properties of the materials as specified by 3D printing company, De Valk. Due to the innovative aspect of our project, it turned out that the parameters of the 3D printing were not always clear enough to predict the final outcome. We had to take account of the fact that a 3D printed object may have different material parameters than that of a solid block of the same material.”

“The assignment was to print the mount in one piece,” Jeroen continues, “That turned out not to be possible because of the support structures required. In some places supports were needed which could not be removed afterwards. In addition, the orientation in which to print was not feasible for all flexures. For example, the rotation stage needed a different print orientation than the translation stage.

The prototype: a 3D metal printed optical mount

The prototype: a 3D metal printed optical mount

Renate agrees: “This presented a geometric challenge, but we managed to produce the prototype and were able to test it using a laser and a target. We sent the laser beam through the beam splitter and started in the centre of the target. Then we flexed the optical mount to see how far it deviates from the centre of the target. The displacement or angular rotation can subsequently be determined from this.”

All in all, the students look back at a fulfilling project in which they learned a lot and gained experience in working with mounts and 3D printing. The best thing: starting with nothing and then handing over something tangible, in which everything comes together. Chris van Lieshout agrees: “We are very pleased with the result. We delivered a 3D printed adjustable optical mount. The model that has been printed needs to be further optimized, but our research and prototype has put IBS on the right course towards this optimization.”

De Valk Added Value Metals contributed to this project by sharing knowledge and experience and by producing the 3D parts. John Hagelaars, director: “We have experienced the project with the students as fun, educational and pleasant. What we have learned as a 3D printing company is the increasingly better transfer of knowledge and lessons learned from the past. The students handled the challenges well and asked the right questions. If the students had any questions, we liked that they didn't hesitate to ask them straight, so that we could help them quickly. They took the advice well and implemented it in the right way. The project had outstanding results and the presentation was excellent! There is still room for improvement but this project was a good start for a new realization of the ARINNA mount. In the designs, for example, profit can be made by approaching even more the design rules of production technology such as 3D metal printing, e.g. by using more organic shapes and thinking even more about the print orientation. We look forward to a continuation of the cooperation with students and IBS.”

On our way to a monolithic, optical mount...

On our way to a monolithic, optical mount...

“The assignment started as an explorative research into possibilities and yet also led to a tangible object.”, concludes Leonardo: “IBS has gained new insights into what is and is not possible in 3D printing. Our project shows what to consider and how to solve a number of problems with 3D printing for optical mounts. Our research provides a basis for further optimization of the mounts.”

Renate adds: “On top of that, our project turned out to be the most appreciated of the 6 presentations for Mechanical Engineering in our year, gaining the highest marks. Especially because despite all the challenges, we managed to deliver a tangible product.”

“The end result is a good start towards a monolithic system”, confirms Rens: “The students were proactive and continuously came up with good ideas. As their instructor, I could take on a role where I could answer questions as a customer, which was very nice. We were pleased to see that the students received top marks for this project from the Fontys Hogeschool. Our experience with this student group was very positive and we are now working with a new group of students for a follow-up project on ARINNA.