- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

Air Bushings provide a frictionless alternative to ball bearings. If you need to achieve precision or high speed linear or rotary shaft motion, they provide the ideal solution.

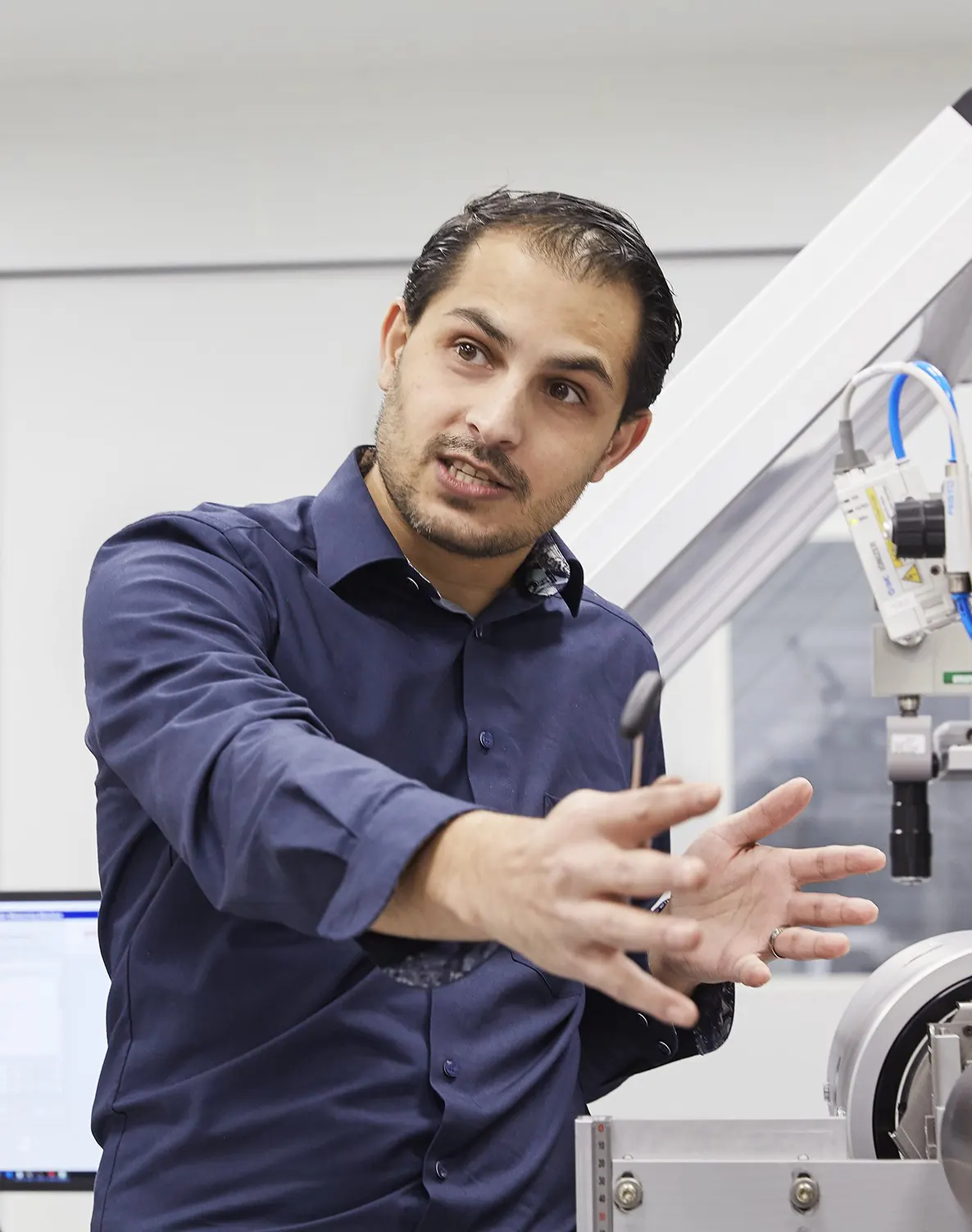

Our engineers can guide you on the right component for your application.

Air bearings are tested by our expert measurement team.

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

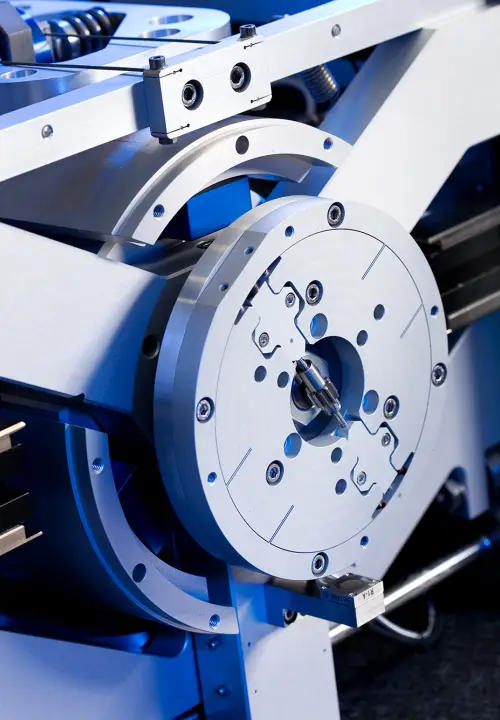

Our Air Bushings are designed to make Air Bearing technology readily available to engineers with pre-existing designs based on round shaft guides.

Air Bushings are, essentially, a tube of Porous Media. Applying an air pressure of 0.41 MPa creates a 4 µm layer of air between the Air Bushing and a shaft. The Air Bushing is designed so that a self centering force is created by the air flow, allowing for true 360° non-contact motion on round shafting. The paralleling force over the length of the bushing centers the shaft naturally, creating precise, non-contact motion in one axis.

The resulting frictionless motion eliminates the heat and vibration commonly associated with roller contact or recirculating ball linear way arrangements. The self centering force also allows for higher than standard rotational speeds.

mm

An air bushing is a frictionless alternative to ball bearings. This non-contact bearing for linear and/or rotational motion uses a thin layer of pressurized air to support a shaft and enable smooth, frictionless motion. The design dramatically reduces friction and wear, compared to traditional bearings, which makes them suitable for:

Air bushings are used in a variety of markets due to their ability to provide frictionless linear or rotational motion. For example:

We can help you find the perfect air bushing for your specific application. Feel free to contact us straight away.

Air bushings are an excellent choice for both cleanroom environments because they don’t need lubricants or oil and don’t generate particulates. This makes them ideal for applications where cleanliness is critical, such as:

Are you wondering if your application is suitable for air bushings? We can help you choose the right air bushing. Feel free to contact us straight away.

Air bushings are especially designed to support radial loads, and they do so through the compressive strength of the pressurized air film. The maximum radial loads depends on the applied air pressure.

For example; 75 mm air bushing:

While air bushings can handle significant radial loads, they are typically used in applications where precision motion, low friction, and no wear operation are more important than high load capacity.

Are you wondering if your application is suitable for air bushings? We can help you choose the right air bushing. Feel free to contact us straight away.

Air bushings typically require:

Oil-free compressors or centralized industrial air systems are common sources for good quality air supply.

More detailed information about the air supply is explained on our operation, cleaning and care page.

Are you wondering if your conditions are suitable for air bushings? We can help you choose the right flat air bearing. Feel free to contact us straight away.

They are used for mounting the air bushings and have 2 main tasks.

The standard mounting method allows the air bushing to “float” somewhat in the housing to allow the air bushing to align axially with the shaft and accommodate misalignments of air bushings and shafting of up to 0.05 mm. When choosing for hard mounting the bushing using epoxy, the air bushings are positioned in the PI with the four o-rings to achieve maximum rigidity. How to apply the epoxy in the pillow block is described in our Air bushings Installation Guide.

Do you have more specific questions about air bushings? Feel free to contact us straight away.

It is recommended to use a two-part epoxy that cures fully without requiring any special catalysts, bonds strong to metal surfaces, and has a suitable viscosity. Shrinkage is generally not an issue when bonding air bushings to mounting blocks. However, additional factors like outgassing should be taken into account based on the operating environment of the air bushings. While most epoxies generate heat during curing (exothermic reaction), the small quantity used for bonding air bushings typically makes this negligible.

How to apply the epoxy in the mounting block is described in our Air bushings Installation Guide.

Are you wondering if you need to hard mount your air bushings using epoxy or need more information on how to mount them? Feel free to contact us straight away.

More questions? Read more Air Bearings FAQ's