- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

For increased positioning precision and load capacity at high speed, these bearings offer advanced motion control engineering.

Our engineers can guide you on the right component for your application.

Air bearings are tested by our expert measurement team.

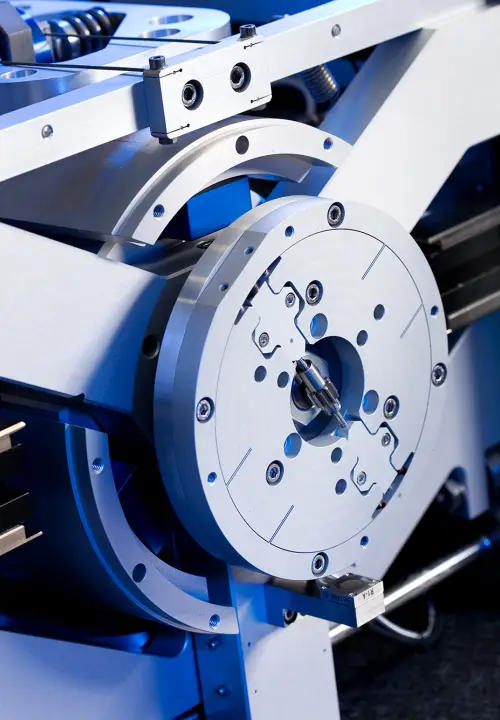

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

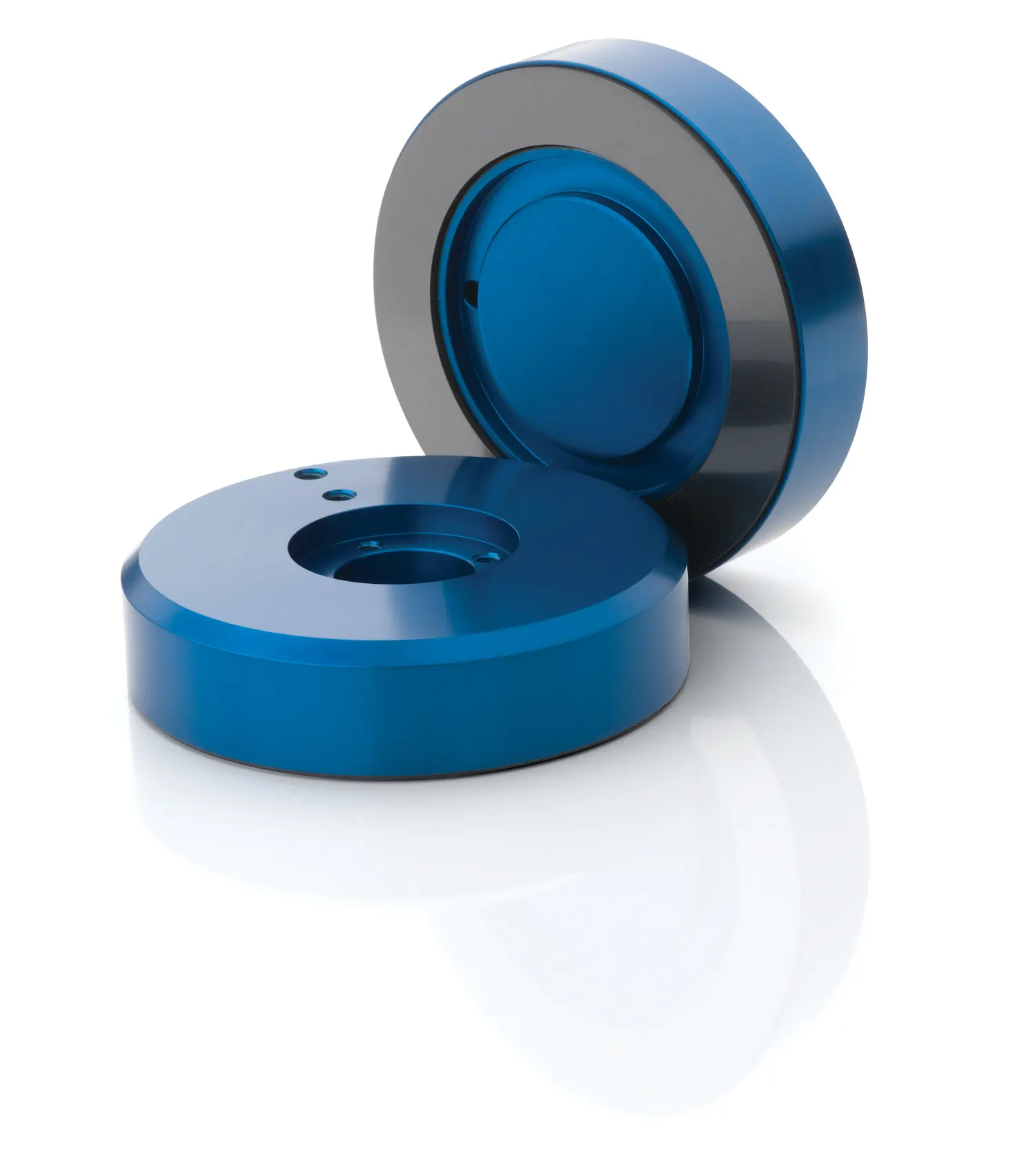

For applications where pre-loading is difficult or impossible, Vacuum Preloaded Air Bearings (VPLs) provide the solution. Our Vacuum Preloaded line replaces a portion of the surface area of our Flat Round Air Bearings with a region dedicated to vacuum pressure. This combination of vacuum and air pressure can be finely tuned to adjust the fly height and stiffness for superior damping. This means that only one flat guide surface is necessary instead of two parallel, flat guide surfaces as in opposed bearing preloading.

Incorporating vacuum increases positioning precision and enables high-speed linear motion. Stiffer air gaps combined with no contact motion means you have higher load bearing capabilities while eliminating the possibility of production stopping crashes.

mm

A vacuum preloaded air bearing combines air pressure and vacuum to provide precise control over fly height and gap stiffness. Using porous media, air is evenly distributed through the bearing surface, creating a frictionless thin film of air. The other part of the bearing surface is dedicated to vacuum, which creates an opposing force that pulls the bearing closer to the guide surface. This removes the need for an opposing bearing or added mass and allows the use of only one flat guide surface. By adjusting the air and vacuum pressures, the fly height and stiffness can be finely tuned. This results in higher load capacity, improved damping, and reliable performance for high-speed and ultra-precision applications.

Vacuum preloaded air bearings are typically used when there is no possibility for an opposing air bearing or force. Such as in situations where an air bearing must be used upside down or where mounting an opposing air bearing or force is difficult or impossible. In such situations they offer reduced system cost and complexity. They are also applied where substrate flattening is an advantage, such as for inspection or printing. Vacuum preloaded air bearings can be used in the same applications and industries as flat air bearings, such as:

We can help you find the perfect vacuum preloaded air bearing for your specific application. Feel free to contact us straight away.

As for regular air bearings, flat and smooth guide surfaces with a suggested finish of 0.4 Ra in µm are required for optimal performance of vacuum preloaded air bearings. Common surface materials are:

Are you wondering if your conditions are suitable for vacuum preloaded air bearings? We can help you choose the right vacuum preloaded air bearing. Feel free to contact us straight away.

No, not in all directions. Vacuum preloaded air bearings mounted in a horizontal orientation can provide excellent support for vertical load but cannot support loads in horizontal, rotational or other directions. To support multiple load directions, a combination of air bearings or a specialized geometric configuration is required. Such as brackets or guides.

Are you wondering if your application is suitable for vacuum preloaded air bearings? We can support you with system design and consideration for the right vacuum preloaded air bearing. Feel free to contact us straight away.

Air: vacuum preloaded air bearings typically require:

Oil-free compressors or centralized industrial air systems are common sources for good quality air supply.

Vacuum: The specific requirements depend on the desired preload, bearing size, and application, but as a rule of thumb:

The vacuum flow rate is about 50% of the air flow rate, because it functions as a closed ring in which half of the current flows outwards to ambient and the other half flows inwards to the vacuum chamber.

Are you wondering if your conditions are suitable for vacuum preloaded air bearings? We can help you choose the right vacuum preloaded air bearing. Feel free to contact us straight away.

A flexure mount is required, which provides a controlled fixation. These flexure mounts supply bi-directional stiffness, a low pivot point and extremely fine angular adjustment. This allows the bearing to stay accurately positioned while still making the tiny self-alignment motions needed for the vacuum preload and air film to establish correctly.

Do you need help mounting your vacuum preloaded air bearings? We can help you get started with vacuum preloaded air bearings. Feel free to contact us straight away.

More questions? Read more Air Bearings FAQ's