- Engineering

- Measuring systems

- Machine qualification

-

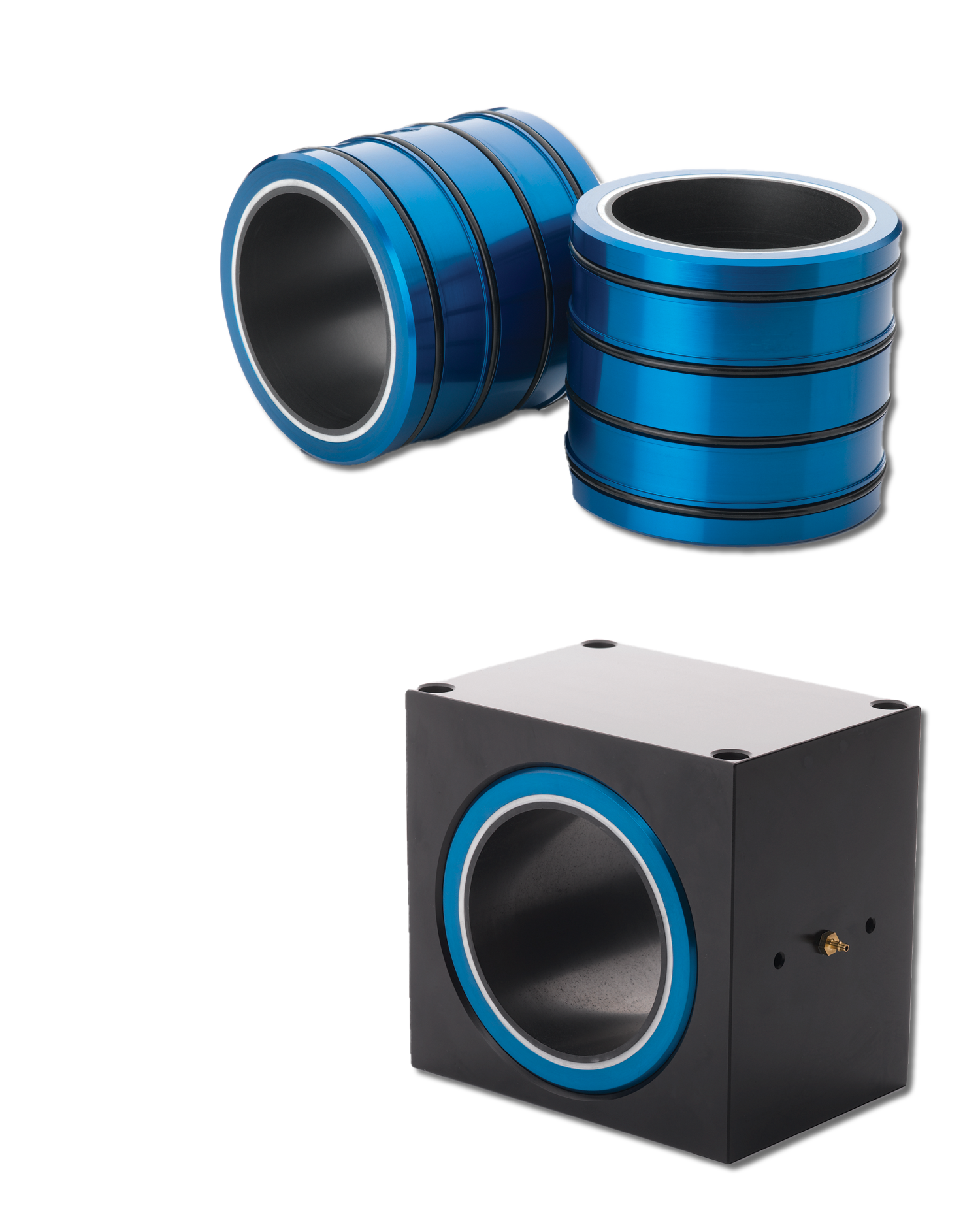

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

Air bearings allow for frictionless motion for torque measurement and calibration. Read Magtrol's Case Study to learn how they use air bearings in their testing set-up, measuring torque and its effect on motor power.

Torque measurements are critical to system performance for rotary motion applications such as engines or spindles. Precision measurement is key to optimising performance. At IBS we are expert in the application of air bearings for frictionless testing. With a focus on innovation and quality, our solutions enable you to create outstanding products, including all you need for a digital twin.

Results in infinite resolution and very high repeatability.

Non-contact zero wear ensures consistent performance and no noise or vibrations.

Air bearings can reach high speeds and high accelerations with minimal heat loss.

Eliminating oil problems. They are self-cleaning by positive air pressure.

Air bearings are not directly influenced by surface finish and irregularities

To test the performance in a virtual environment upfront.

“The combination of great support,

zero friction performance and a wide

product portfolio makes this product range

our go-to assortment for air bearings for

upcoming projects."

Maxwell Keeling

Product Development, Mechanical Engineer

Applications: dynamic torque measurement, torsional load measurement, moment of force, rotational force measurement, frictionless rotation, tribology, electrical drivetrain, electromobility, energy transition in automotive.