- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

- About IBS

Testing systems are used extensively in the automotive industry. The challenge is: How to prevent friction from affecting test systems and results? Applying the right motion technology in vehicle test systems is critical for obtaining uncompromised performance optimisation. Frictionless motion and positioning is the solution for precision results.

The development of new vehicles brings about numerous test and measurement challenges in the process to reduce development time, increase quality and decrease product failures. IBS Precision Engineering is your ideal partner for engineering solutions with non-contact porous media air bearings for test set-ups. The many technical advantages of air bearings such as near zero friction and wear, high speed and high precision capabilities, and no oil lubrication requirements are powerful features and help test engineers to build perfect test conditions. At IBS we are expert in the application of air bearings for frictionless testing. We offer the broadest range of top performing air bearings, including specials engineered to order.

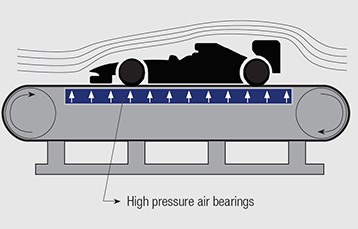

When testing (race) car aerodynamics in windtunnels, it is essential to simulate on-road conditions. High pressure air bearings in moving ground systems (rolling roads) avoid upward suction of the belt in areas of rapid air movement and guarantee zero friction between belt and bearing. The air film stabilizes and cools the belt and thus reduces the drive power needed for the moving ground system.

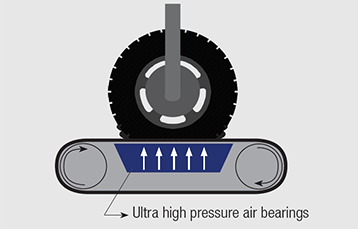

Understanding the conduct of tyres and tyre mechanics is key in determining their influence on the ride, handling and safety of sport cars and commercial vehicles. Tyre testing is critical to conform to legislative requirements and to improve the overall tyre performance. Test set-ups with ultra high pressure air bearings (up to 25 bar) ensure friction free testing supporting high forces.

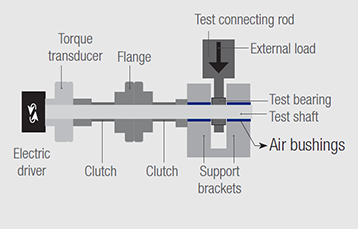

From R&D to manufacturing and compliance testing, measurement of powertrain not only requires progressively greater accuracies but also consistency in measurement over the specified ranges and conditions. Non-contact air bearings guarantee friction free rotational motion for torque test systems and bearing & seal measurements.

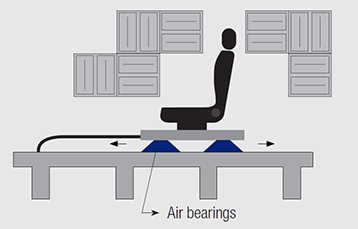

The volume and noises emitted by assembled vehicles are the result of complex interactions. They vary during different movements in different conditions. Tuning out unwanted noise, vibration, and harshness requires sophisticated test equipment. Noise emitted by air bearings is close to zero, making them ideal as silent motion systems in sound-proof chambers set-ups.

“The combination of great support,

zero friction performance and a wide

product portfolio makes this product range

our go-to assortment for air bearings for

upcoming projects."

Maxwell Keeling

Product Development, Mechanical Engineer

Applications: Aerodynamic and wind tunnel testing, vehicle dynamic testing, vehicle simulation, tyre force testing, tyre torque measurement, tyre rolling resistance testing, torsional load measurement, rotational force measurement, measurement of bearings and seals, roundness measurement of cylinders, noise testing of interior parts, NVH testing, noise measurement of fuel tanks, tribology, electrical drivetrain testing.