- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

We work closely with our customers to deliver unique air bearing solutions with optimised features to meet demanding application challenges. Custom air bearings are used in a wide range of applications, including aerospace, automotive, industrial and medical equipment.

IBS has a rich history of delivering precise solutions for complex engineering challenges. Alongside our wide range of off-the-shelf air bearing products designed for linear, rotary, conveying and web handling applications, we also offer comprehensive engineering services for bespoke air bearing solutions. Together with our partner New Way, we have the capability to design entirely new, non-contact air bearing solutions that are precisely tailored to your specific needs and we possess the expertise to integrate them seamlessly in to your precision application.

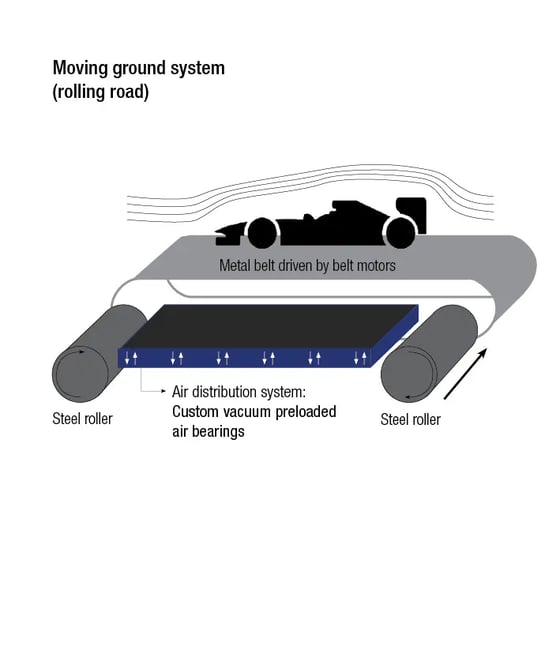

Flat rectangular air bearings offer a non-contact solution for high-load linear applications, including wind tunnel testing in the aerospace and automotive industry. A new rolling road belt system for a wind tunnel, which utilizes a 1-mm thick metal sheet on large hardened steel rollers, needed the support of 750 custom-made vacuum pre-loaded air bearings, a sophisticated suction/blowing system, to keep the belt flat under large aerodynamic loading when testing aircraft in ground proximity. A dedicated air compressor supplies pressurized dry air at 10 bar with a dew point of -30⁰C, along with two 55 kW vacuum pumps to maintain belt stability under significant aerodynamic loads.

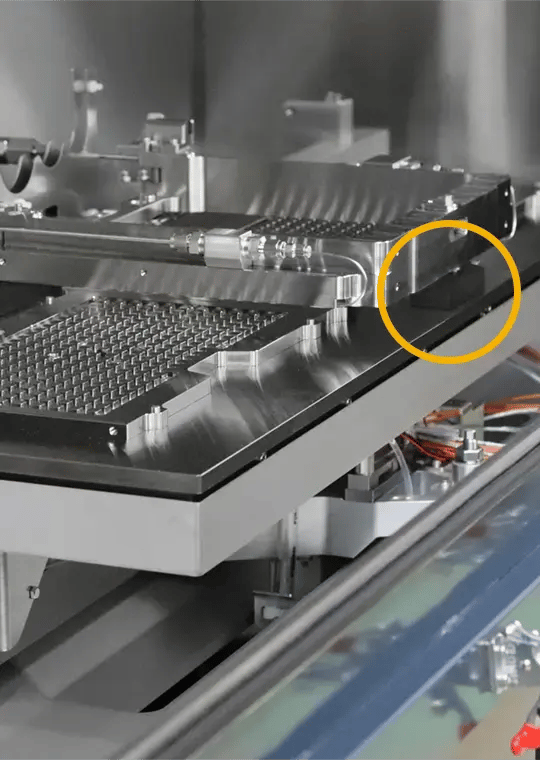

In Spatial Atomic Layer Deposition (SALD) equipment, the manufacturer required a design featuring a rigid structure and a consistent process gap between the moving substrate and the injector head. Supporting the injector head directly on the moving substrate table using air bearings would provide an accurate, scalable and cost-effective solution. Components should withstand maximum temperatures of 250°C, maintain a particle-free production environment and prevent grease contamination. IBS recommended custom-made full carbon air bearings capable of enduring temperatures up to 250°C. These non-contact air bearings, without housing, create a stable and frictionless air gap between the injector frame and the moving substrate table. IBS collaborated on the design to ensure proper air supply and mounting of the full carbon air bearings. The use of these bearings resulted in a stable, lubricant-free and particle-free process gap at high temperatures, with infinite performance lifespan and zero maintenance requirement.