- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

- About IBS

With ultra-high positioning accuracy, super high speed performance and zero friction, porous air bearings are the ideal choice for precision machines and test rigs; from semicon to automotive and advanced printing, their unique advantages are being applied. They also minimise heat, contamination and noise. Get inspired by the air bearing applications mentioned below.

High-resolution direct laser writing is a powerful technology for creating micron to sub-micrometer resolution structures in photo sensitive layers. The laser beam systems (optical lithography) that create the optical patterning are guided with ultra-precision by frictionless air slides; to guarantee a nano-precise control of the laser beam in the production process.

Products:

> Air slides

> Air bushings

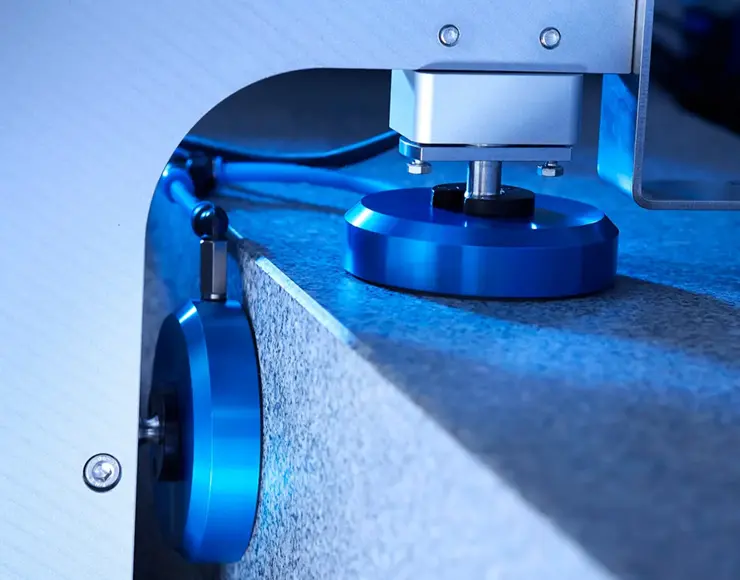

3D metal printing technology, one of the most accurate forms of additive manufacturing, is able to create microscopic details, great dimensional accuracy and variable diameters, due to a very precise production process. In this process the object is built layer by layer, using metal powder and high-precision binder jetting. Frictionless flat air bearings and air bushings are used to accurately move and position the high-precision jets over each new layer of metal powder. The performance of the air bearings is not effected by residue powder particles in the environment.

Products:

> Flat air bearings

> Air bushings

The latest generation of surface mount pick and place machines set new records in speed, floorspace performance and accuracy for high-volume production applications. Smart factory solutions in the electronics manufacturing industry require improved efficiency of production. High speed and acceleration plus high accuracy positioning of the placement heads is increasingly performed with the use of frictionless, maintenance free air bushings.

Products:

> Air bushings

Printing has required precision for many decades as the human eye is very sensitive to accurate registration of colours. Today however, large cylindrical printing equipment parts must achieve sub-micron (<10⁻⁶ m) level accuracy over ~5 meters. Qualifying these parts requires advanced co-ordinate metrology machines. Air bearing technology allows frictionless linear and rotation movements to support micron level accuracy and repeatability during inspection in these machines.

Products:

> Flat air bearings