- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

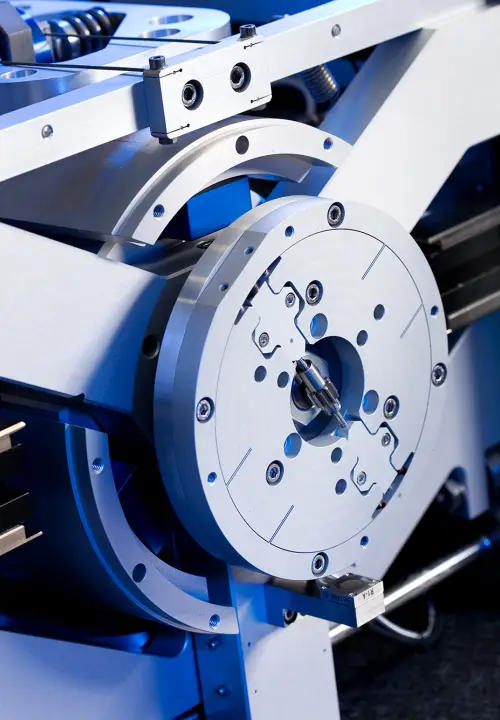

Air Spindles utilize porous media technology to create a uniform cushion of air between the rotor and stator. This enables faster rotation speeds and high-precision rotary motion with less interruption or possible down time due to zero mechanical wear.

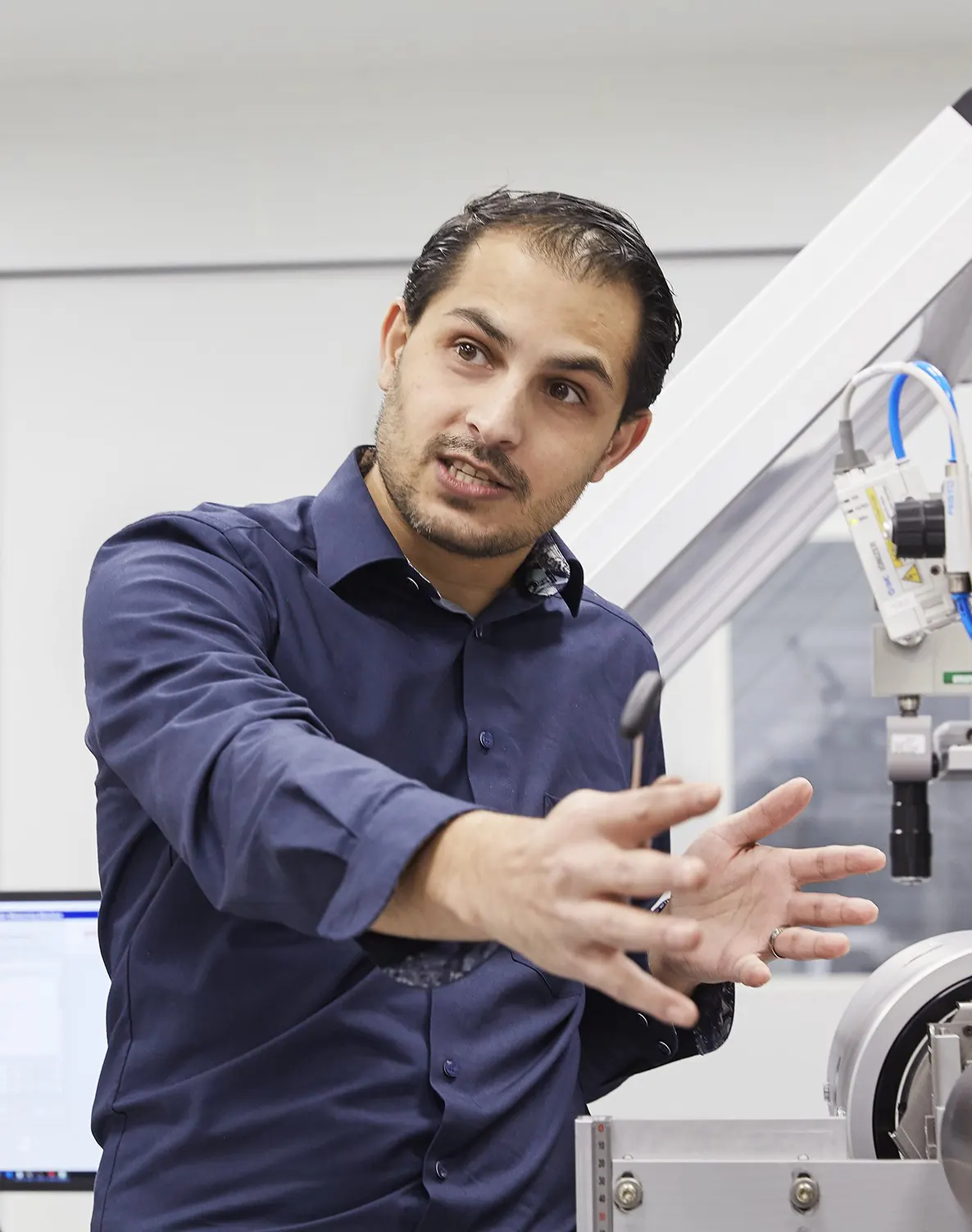

Our engineers can guide you on the right component for your application.

Air bearings are tested by our expert measurement team.

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

Air Spindles utilise Porous Media technology to establish a uniform air cushion between the rotor and stator. This facilitates faster rotational speeds and high-precision rotary motion with minimal interruptions or potential downtime due to the zero mechanical wear.

These Air Spindles provide a level of accuracy unachievable by conventional rolling element bearings. Featuring just a single moving part and absolutely non-contact, they offer standard sub-micron synchronous error motion, while almost completely eradicating asynchronous errors.

Air Spindles have minimal airflow requirements and do not consume anywhere near the volume of air that competing orifice air bearing technologies do. If there is any disturbance in the airflow, the gradual depressurisation of the Porous Media enables a gentle landing that avoids damaging the bearing or rotor surfaces. This sets them apart from orifice air bearing spindles, which frequently demand a full rebuild following such malfunctions.

mm