- Engineering

- Measuring systems

- Machine qualification

-

Components

-

Systems

-

Learn more

-

- Expertise

-

About IBS

-

Our Story

-

Learn More

-

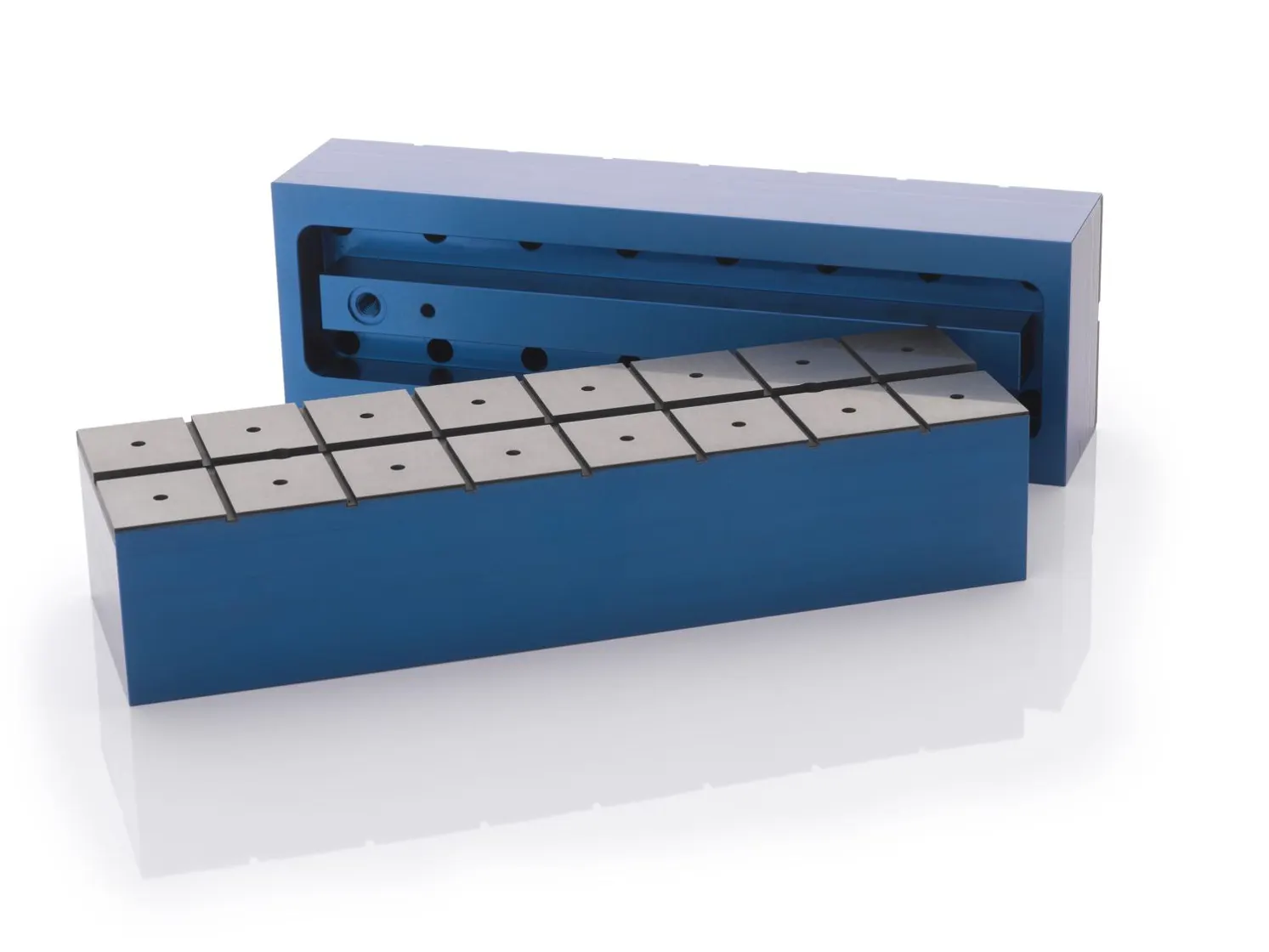

The ideal component for inspection as an air cushion combined with a tight array of vacuum points delivers nanometer surface stability.

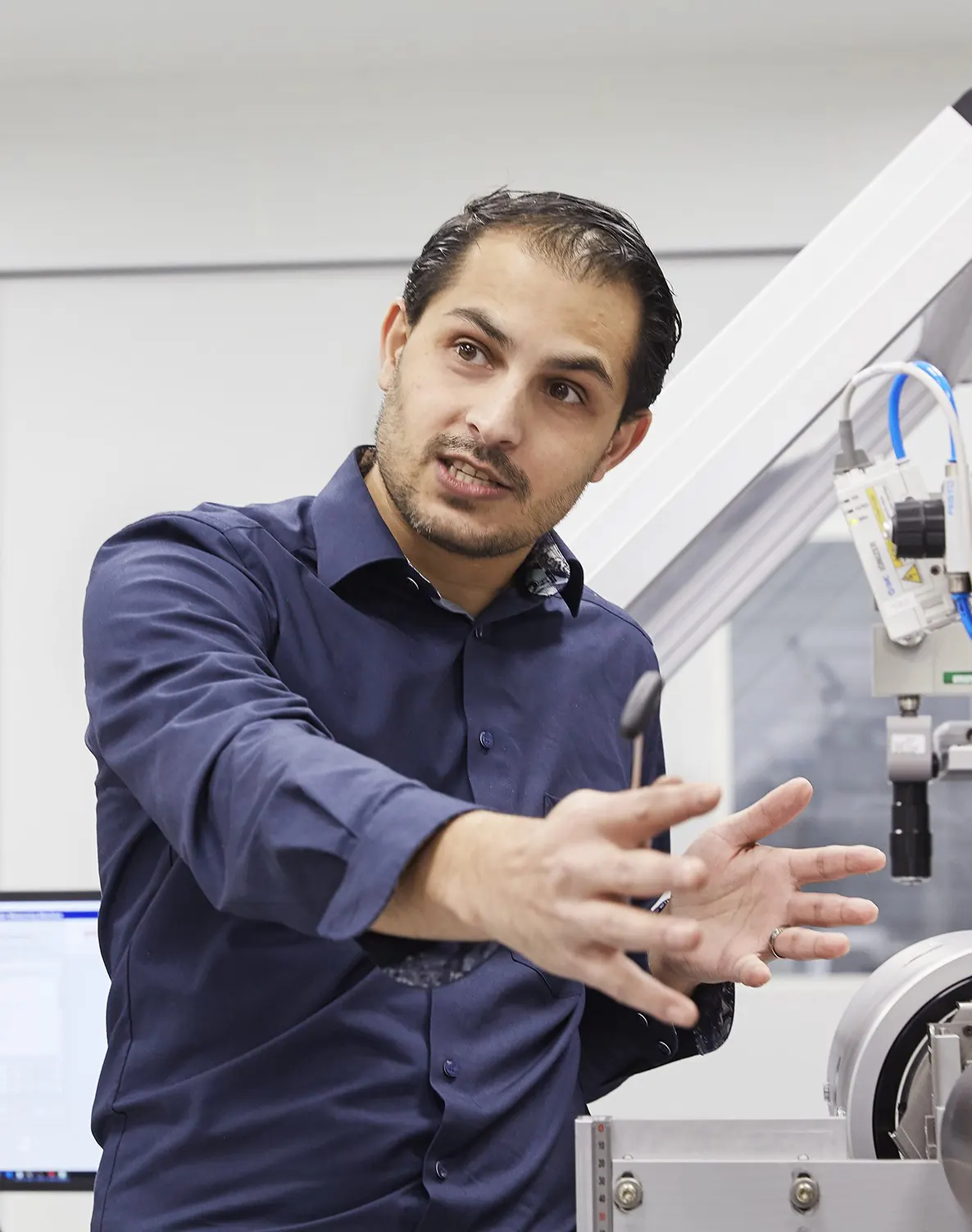

Our engineers can guide you on the right component for your application.

Air bearings are tested by our expert measurement team.

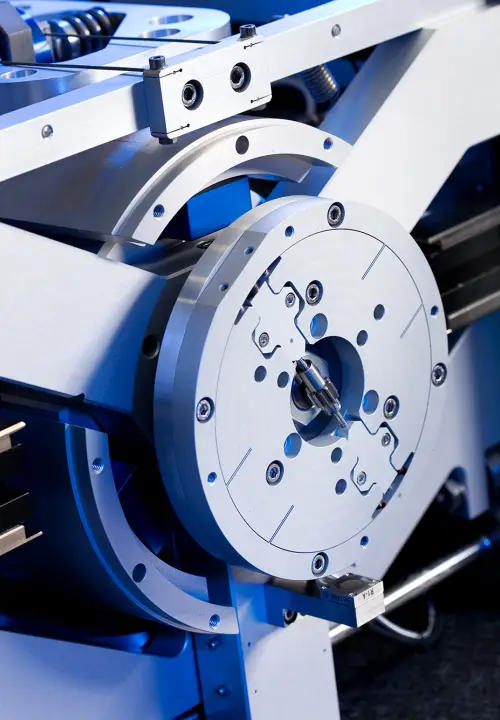

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

The Precision Zone Series offers the highest level of precision for fly height and control range. Ideal for inspection of specific areas of materials that require high-level analysis for inconsistencies like solar glass manufacturing processes or automated optical inspection (AOI) stations. The design ensures the vacuum pressure and air gaps are the same across the entire bar. This superior stability enables analysis and inspection of a greater percentage of the entire glass sheet.

mm