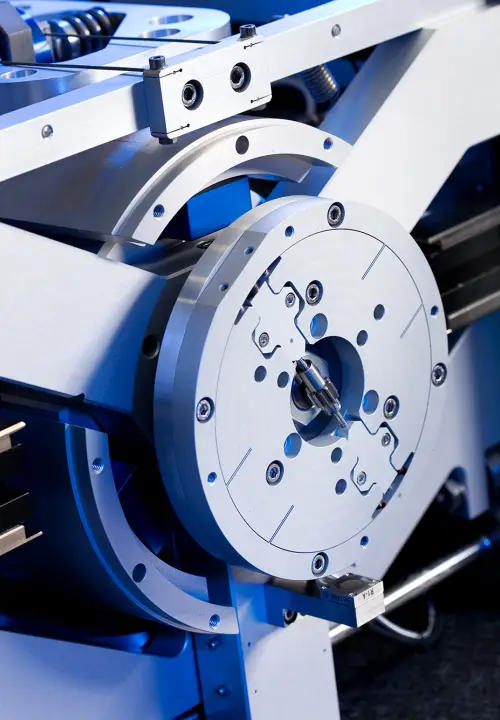

The ideal component for transport of delicate substrates. These conveyors are perfect for high processing speeds as extra vacuum gives superior flattening ability.

Our engineers can guide you on the right component for your application.

Our engineers can guide you on the right component for your application.

Solutions designed for your application.

Whether your challenge is precision, speed or environment, we can offer unmatched experience.

The High Speed Series improves upon the Transition Zone Series through the use of four grooves of vacuum holes. Its excellent flattening ability ensures control of glass or PET at high speeds. The cutting edge Porous Media technology, infused with millions of sub-micron holes, creates robust air cushions, leading to lower fly heights and enhanced overall efficiency. The High Speed series is specially designed for handling flexible substrates, making it excellent for versatile material processing.

mm

We’ll reply within 1 day.